Committed To Quality, Committed To You

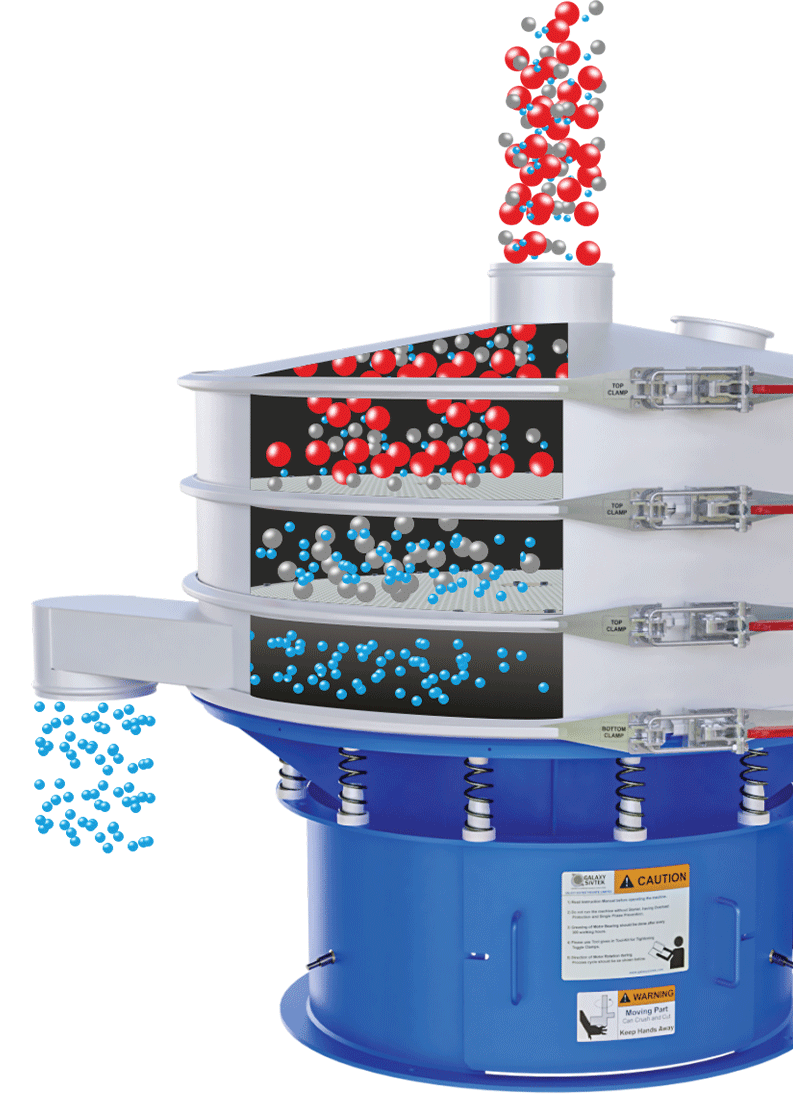

With the help of eccentric weights that are mounted on the upper and lower ends of the motion generator shaft of the machine, Sivtek Vibro Separator achieves the staggering high-intensity vibrations that it is famous for. The dual weights allow the machine to move in a circular motion, as the lower weights aim to tilt the machine to generate vertical vibrations and the top weights move to distribute the materials across the screen.

The SIVTEK Vibro Separator is quieter than any conventional vibro screener.

Machines are designed to be tightly packed so that no particles can leak in or out.

In addition to providing high throughput, they are designed to sort large quantities of materials quickly and efficiently. During vibration, the particles move across the screen, and by falling through the mesh openings, the particles of different sizes are separated.

Sivtek Vibro Separator produce very little noise while processing, resulting in the lowest possible noise levels.

The easy mesh changing clamps embedded in the machine make it very convenient to clean the screener.

Due to the castor wheels, the vibro separator is highly manoeuvrable and requires fewer hands to operate.