Committed To Quality, Committed To You

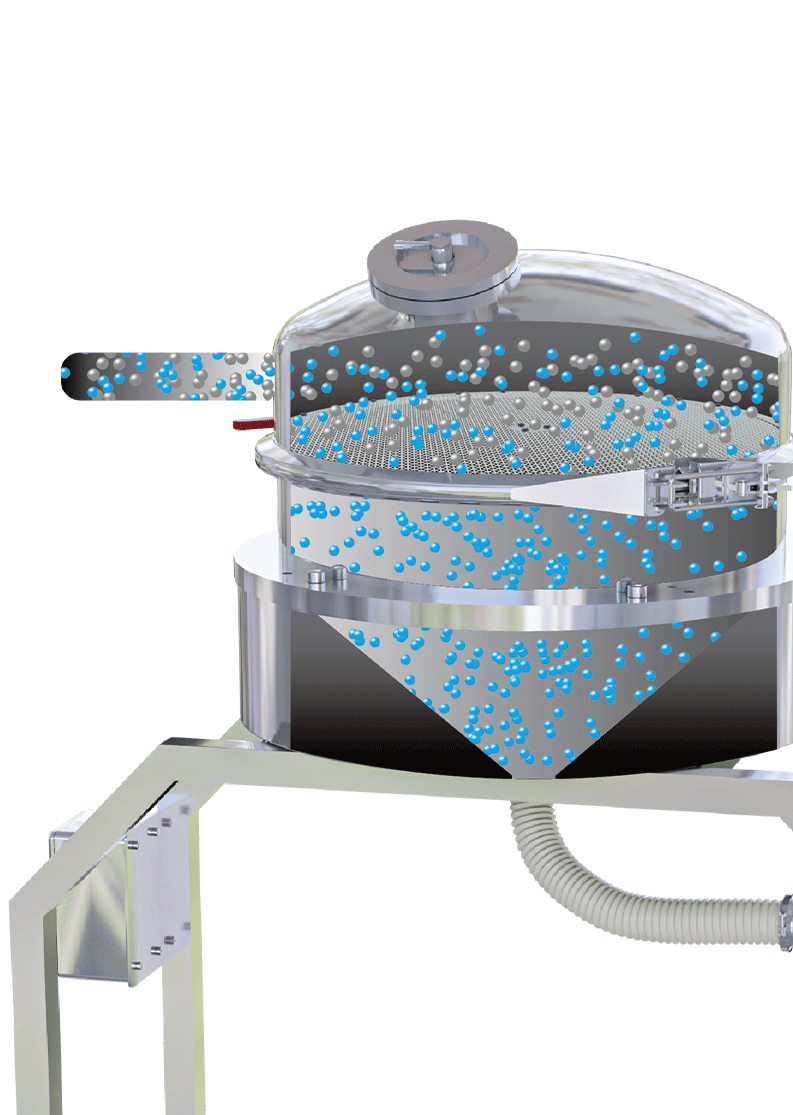

Vacuum Sivtek uses a pneumatic sifter vibratory separator with dilute-phase pneumatic conveying systems to perform in-line pneumatic scalping and dedusting of free-flowing materials. Top and bottom screens are connected by a central bypass chute, which allows on-size materials to enter the central chamber in two ways: upward through the top screen, then downward through the chute, or downward through the button screen. The spout at the lower screen’s periphery ejects any oversize materials that are present.

The machine is tightly enclosed, which prohibits the screening material from overflowing or any other particles from entering the machine. It is 100% contamination-free.

Built with premium stainless steel and precision finishing, the Vacuum Sivtek gives you the highest level of hygiene and safety.

We've installed inspection windows so you can peek inside the machine.

With a noise level below 75DB, the Vacuum Sivtek is quieter than any conventional Vibro sifter.

The Vacuum Sivtek's compact design requires low headroom and fits easily into production lines.

Because the machine is tightly sealed, dust particles from raw materials can't get inside. Hence, you don't have to clean screens all the time.