Committed To Quality, Committed To You

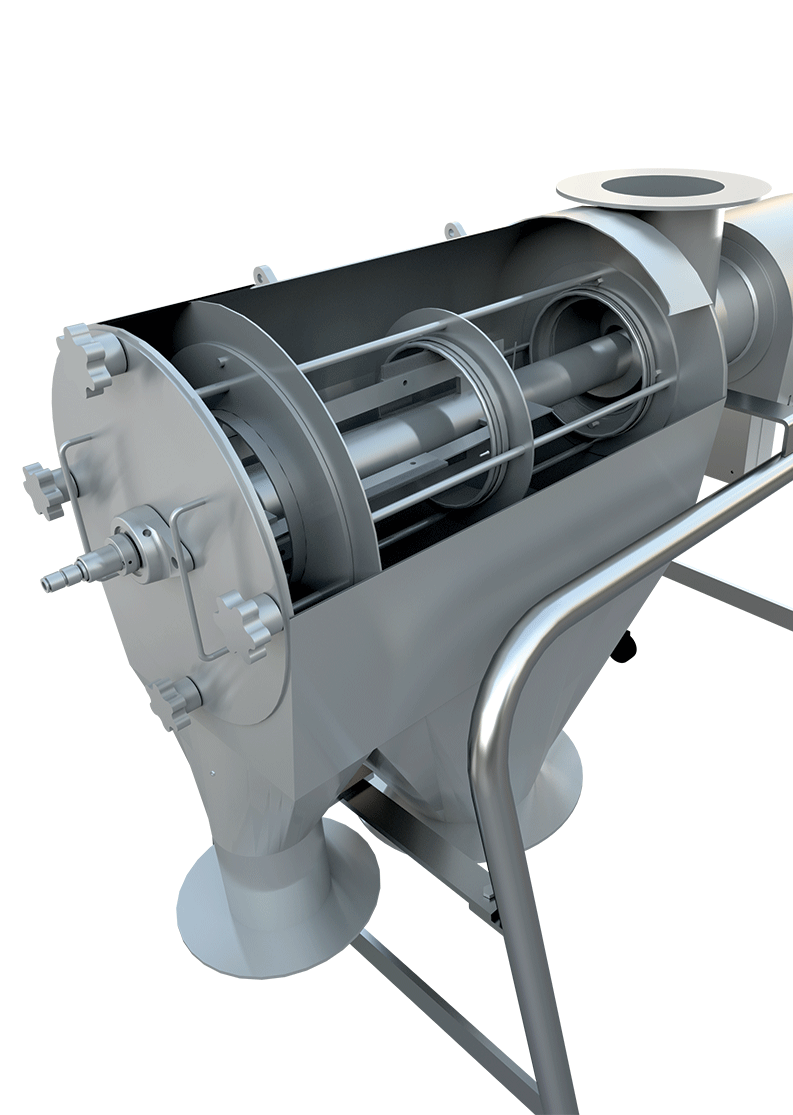

The sifter has a vacuum rating of up to 14 inches (356 mm), providing the capacity and space savings of an independent high-output sifter. Using a feed splitter, the material flow is evenly divided into horizontally oriented cylindrical screening chambers. A shaft rotating a helical paddle assembly accelerated particles and soft agglomerates during the screening process. In an automatic delivery system, oversize particles are ejected while on-size particles pass through apertures in the screens.

In order to monitor the screening process, Sivtek's Pneumatic Roto Sifter® features convenient inspection windows.

The Sivtek Pneumatic Roto Sifter® is firmly designed to contain the screening material. As a result, hazardous substances can be handled with greater safety.

Noise levels are below 80 DB and vibrations are minimal.

Due to its closed system operation, it is capable of maintaining the highest levels of hygienic standards.

Due to its compact design, the Sivtek Pneumatic Roto Sifter® is more flexible and manoeuvrable.

The machine is easy to clean because it has many options and knobs for disassembly.