Committed To Quality, Committed To You

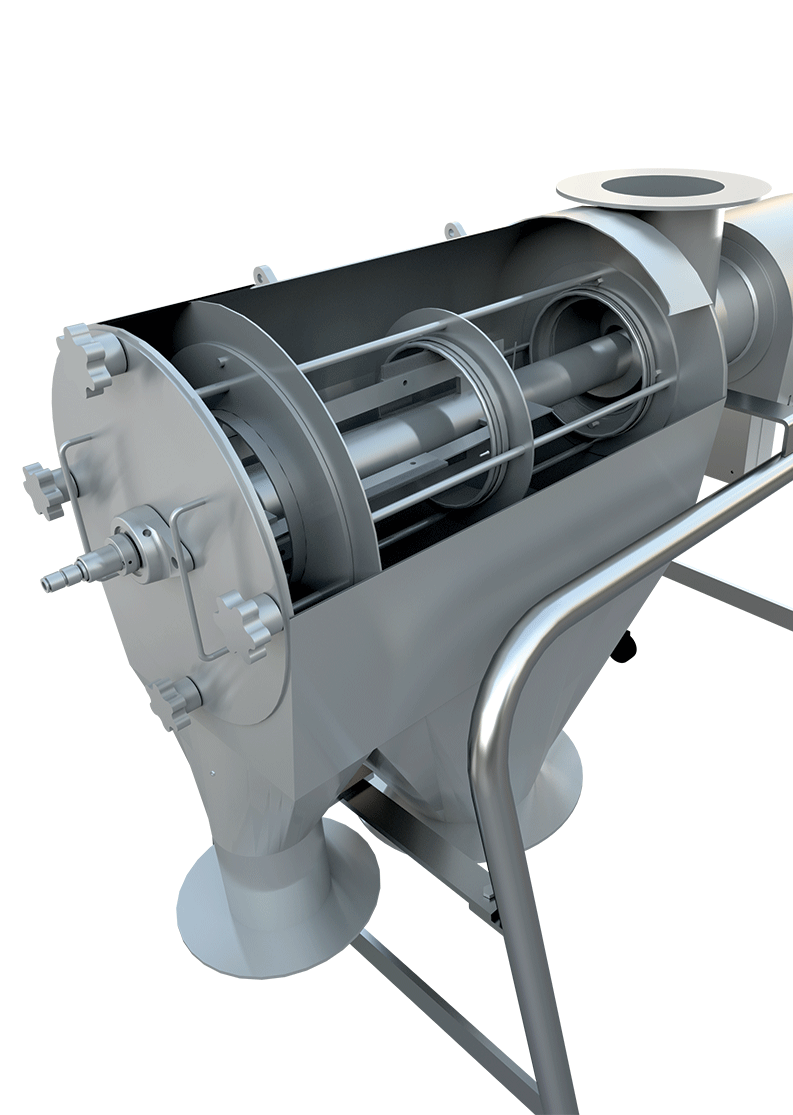

The beater bars generate centrifugal force that propels the raw material against a screen mesh that separates the materials based on their particle sizes. Additionally, it allows you to process the material in a vacuum if necessary. With the cantilever design, you can achieve unprecedented levels of hygiene and sound reduction.

Twin Roto Sifters have two centrifugal chambers, giving them the capacity of two separate machines.

During operation, the machine is operated with minimal vibrations and maintains a noise level below 80 decibels.

The machine's clamping mechanism makes it very easy to remove the screens and inspect them immediately.

You can disassemble the machine so it's easy to clean.

Roto Sifters have a compact design that makes them easier to maneuver.

During operation, the machine produces minimal vibrations and maintains a noise level below 80 decibels.