Client’s profile:

Leading & renowned edible & commercial oil manufacturers & suppliers dealing in oil and oil-related products. As part of its operations, the company produces various edible oils, including refined cottonseed oil, refined sunflower oil, refined corn oil, refined soybean oil, refined groundnut oil, etc. As well as commercial products such as castor oil, de-oiled castor cake, etc.

About the Product:

It was required that the client obtain a robust classifying and de-dusting machine capable of separating Deoiled Castor Cake into three different particle sizes in order to de-dust and classify the cake.

During the extraction of castor oil, a by-product is obtained called de-oiled castor cake. Due to their high commercial demand, residual residues after the extraction of castor beans are highly valuable.

Due to its rich content, de-oiled castor cake also referred to as castor meal, is widely used as manure and fertilizer. Three vital elements are present in it: nitrogen, phosphorus, and potassium. These elements are necessary for the proper growth of crops. Additionally, it is regarded as the most organic and natural manure due to its non-decomposition.

Challenges:

There is approximately 9 to 12 percent moisture in castor meal, which tends to form soft lumps and agglomerates. This creates a blockage in the mesh and hinders the production process, resulting in increased waste as a result of lumps.

Furthermore, the dry castor meal contained very tiny particles that would cause a great deal of dusting while being sorted into a giant vibrating sorter. In the event of heavy dusting, cleaning and maintenance would be required on a regular basis.

Creating a vibrating sieve with a continuous sieving and classification process would solve the problem of lumps and dust, as well as create a system to clean the dust automatically.

– Agglomeration formation leads to product wastage and mesh choking.

– Frequent cleaning and maintenance are required when dusting is heavy.

– An automatic sieving machine that can operate continuously without any interruptions in order to reduce batch processing time.

Are you interested in customized solution?

Contact Us Now: De-dust De oiled Caster CakeSolutions :

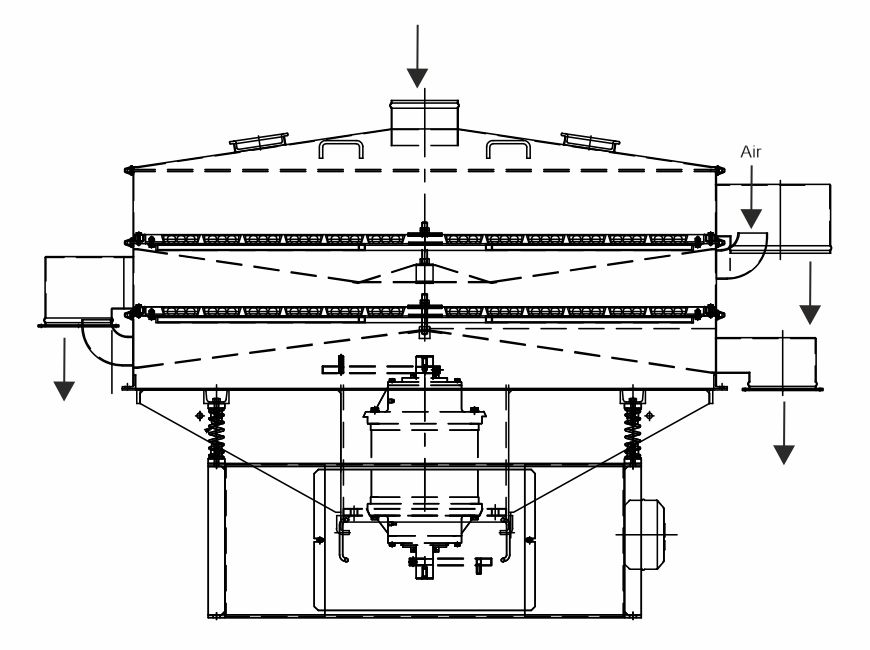

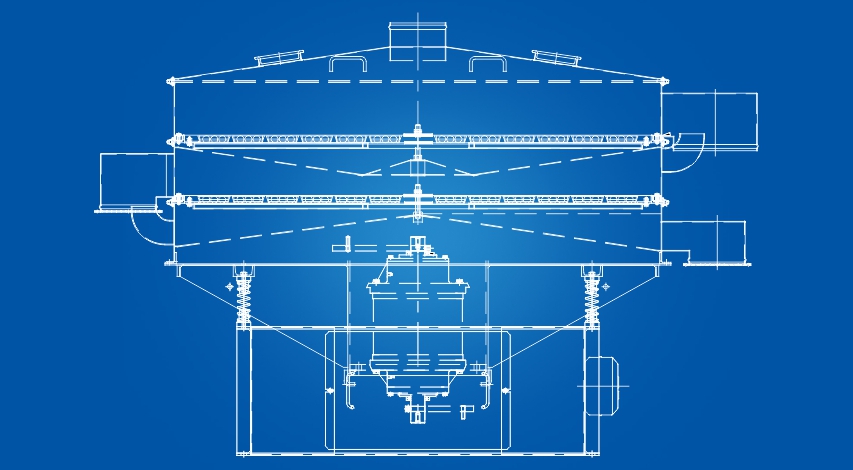

To eliminate dust through air pressure, Galaxy Sivtek’s design engineers designed two giant and unique double-decked vibrating gyro separators. These separators are equipped with pneumatic mesh cleaning arrangements underneath the mesh to remove dust. Each deck was equipped with elbow pipes to facilitate the evacuation of dust.

Due to heavy dusting, pneumatic mesh cleaning arrangements solved the problem of frequent cleaning. Additionally, the pneumatic mesh cleaning system enabled continuous sieving and classification.

Machines were delivered with mesh de-blinding kits (ball tray arrangement) in order to solve the problem of de-lumping & breaking soft lumps.

Rubber balls and trays are placed between a perforated sheet and mesh to remove blind spots. Balls and trays continuously tap the mesh due to the vibrations of the machines, thereby breaking soft lumps effortlessly.

They achieved the classification of castor meal with the utmost ease through the use of two custom-designed Sivtek Super Gyro Separators®, each measuring 72 inches in diameter.

Result

By providing them with a customized solution, they were able to not only achieve the desired results, but also resolve the main problems of cleaning heavy dusting, mesh choking, and product loss.