Case Study: Customized Vibro Sifter for Chilli Powder

Overview

In addition to being an ancient trade, spice manufacturing has evolved over the centuries. Manufacturing steps have remained the same, however, manufacturing technology and processes have changed for the better.

Having a long and established domain in screening & filtering technology, we have been able to capture & provide sieving solutions to the vast market of spice manufacturers.

Requirement & Challenges

The manufacturer of spice powder sought a way to directly send the chili powder for packaging after safety & quality checks to screen to ensure that the chili powder that is being packed is contamination-free.

Understanding the problem requires an understanding of the general process involved in manufacturing chili powder. Chili powder is prepared by cleaning and drying chilies, followed by crushing and pulverizing them into fine particles.

The pulverized material is sieved with a fine mesh to remove contamination and obtain particles of similar sizes.

Having been finely sieved, it is stored in bulk and then it is passed through a final safety screening and manually dumped into the packaging machine’s hopper for packing into different volumes of sachets.

According to the discussion with the Sivtek expert, the company wanted to resolve the issues they had with storage and packaging.

The manufacturer has encountered two main concerns during storage, namely the creation of powder and contamination from human interaction and the external environment.

A significant problem after check screening was the need to manually dump chili powder into packaging lines since it was possible for the powder to become contaminated by human interactions or the ambient environment during manual dumping.

Likewise, manual dumping requires manpower, so resource utilization between the processes was also identified as a concern by the head of the production department.

Solution

To overcome the concerns, they faced, the Design department as well as the R&D department studied the subject thoroughly and agreed on a customized solution.

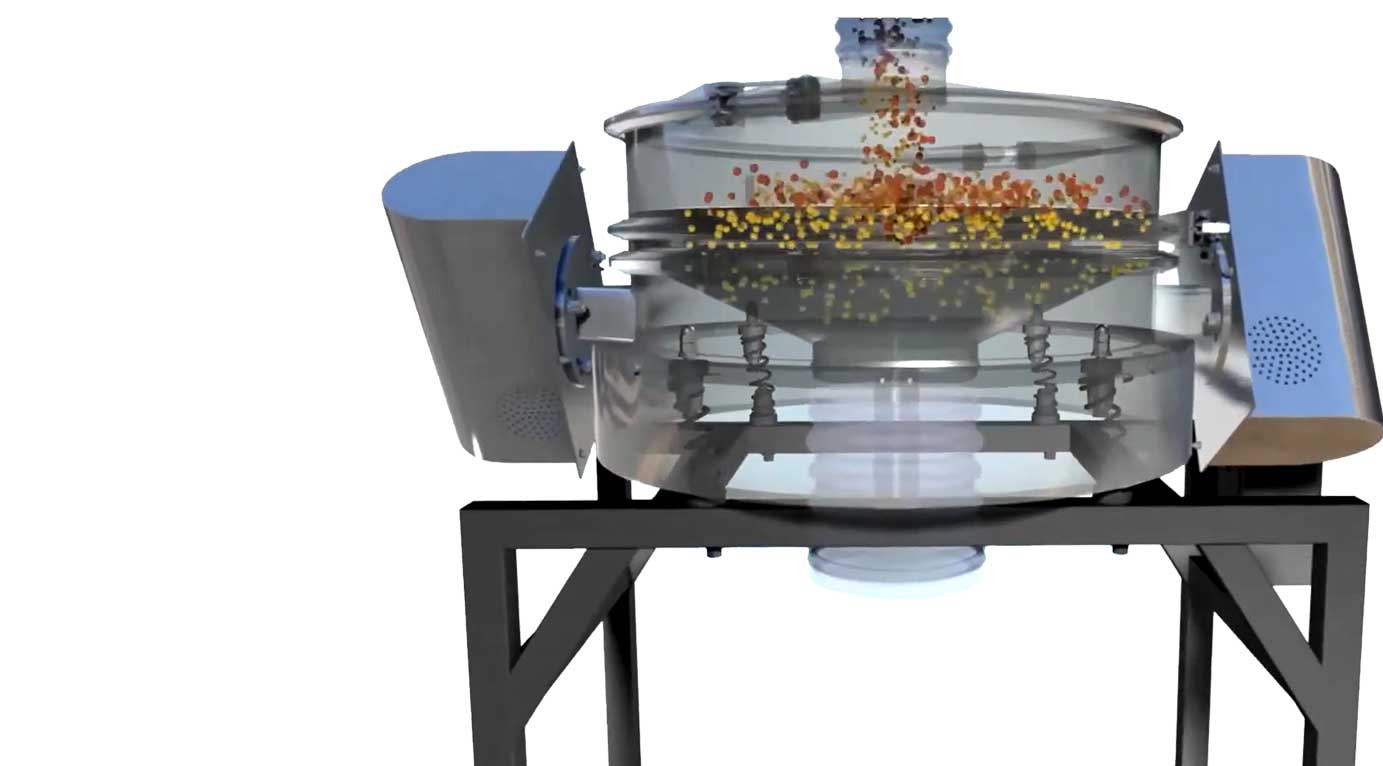

The solution was developed as an enclosed inline Sivtek system with a large mesh opening, a bag resting pad on top, and a screw conveyor at the end.

It must be integrated into the company’s existing product line to be successful.

Mesh with a large opening for check screening.

There is a pad at the top of the bag to prevent the wastage of chili powder during the process of dumping it for check screening.

As a result of an enclosed system and screw conveyor, chili powder can be transferred directly into the packing machine. This is without any chance of contamination or the need for additional resources, as was the case during manual dumping in the past.

Results

In response to his statement that the enclosed sieving solution with screw conveyor reduced contamination to virtually zero percent, the Head of production department was very satisfied. As a result, we were able to reduce manpower & costs by dumping the material for check screening and packaging, thanks to Galaxy’s provision of 16 customized Inline Sifter machines.”