Committed To Quality, Committed To You

Is your screen constantly blinded by fine particles that hinder your efficiency? We have a solution for you. Using Galaxy Sivtek’s innovative Mesh Deblinding Kit, you can prevent such particle clogging and keep your screen clean longer.

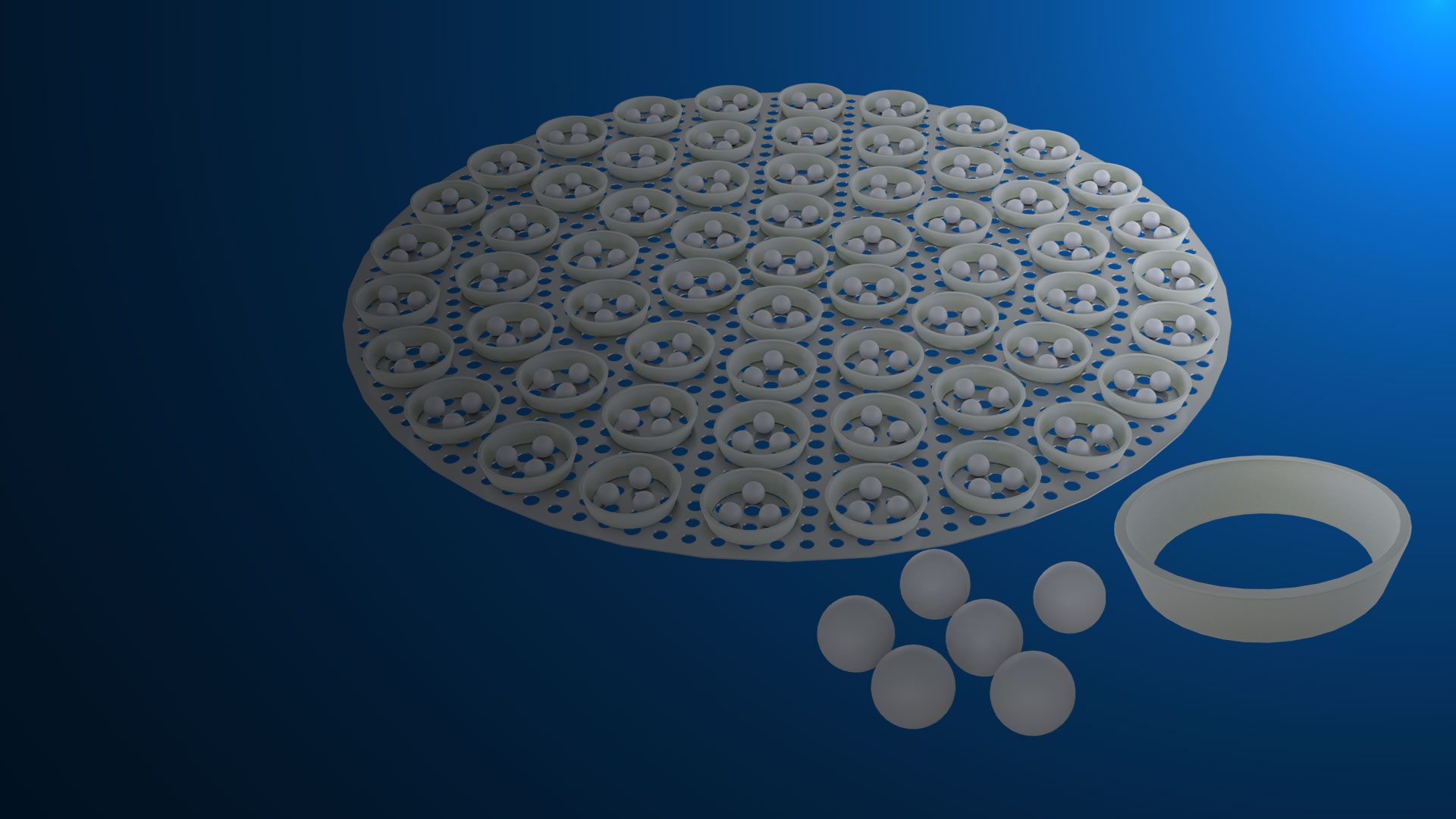

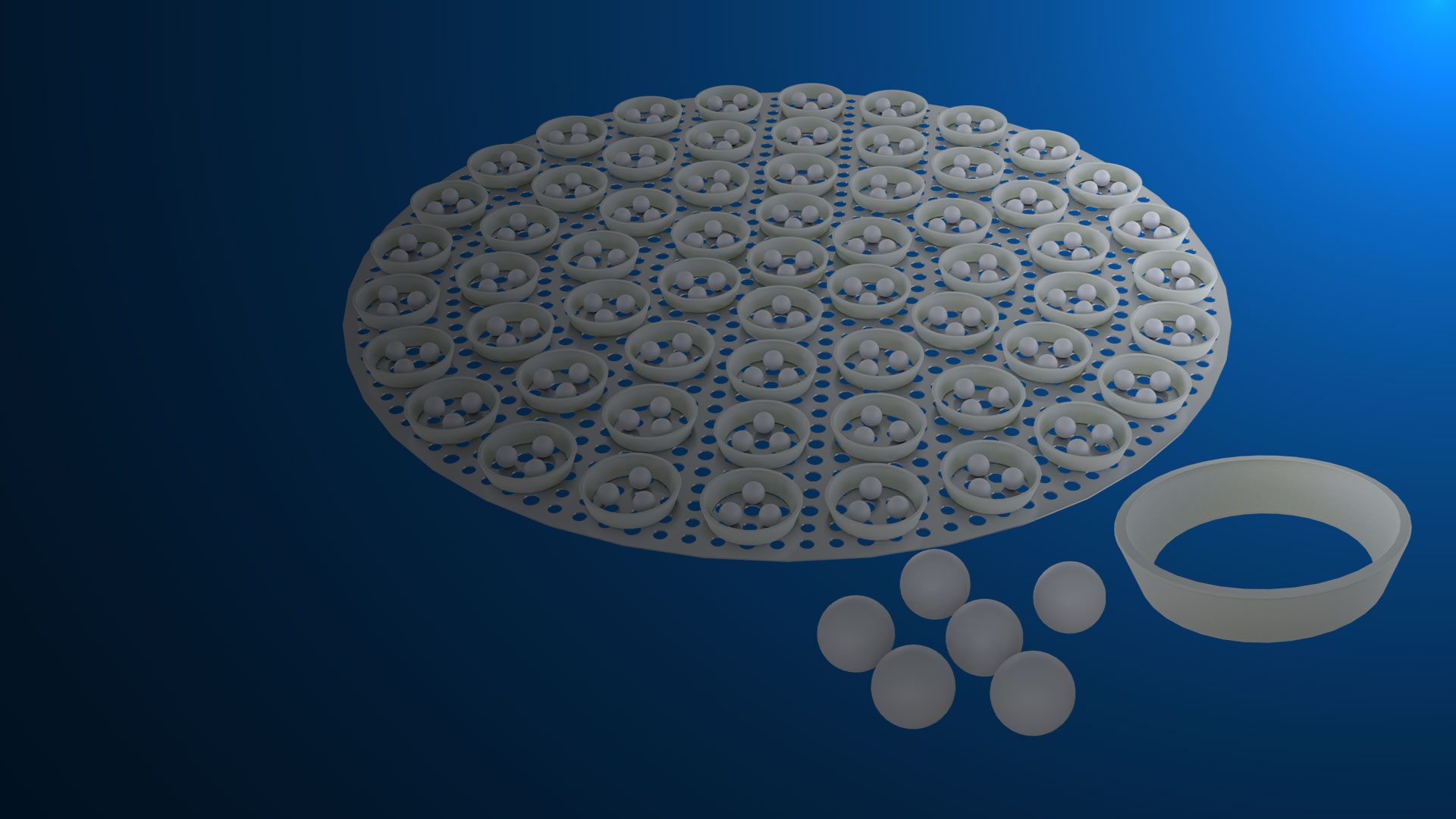

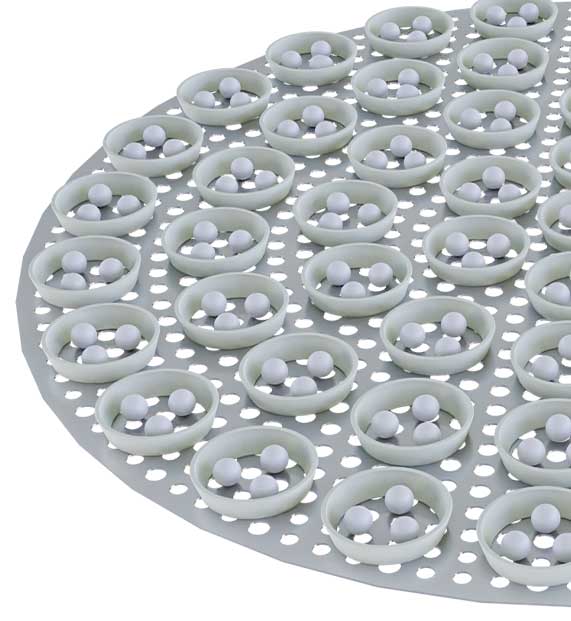

This Mesh Deblinding Kit works primarily on elastomeric balls that are capable of removing any fine particle. When the machine vibrates, the balls bounce and prevent the screening material from clogging in and around the sieve.

Besides improving efficiency and productivity, they also prolong the life of your screens and keep them clean. Additionally, they reduce waste, which contributes to cost reduction.

How the Mesh Deblinding Kit works is that an anti-blinding ball tray, made up of fine mesh, is installed underneath the sizing mesh. There are enough elastomer or polymer balls on the ball tray to constantly tamper with the sizing screen. As the balls keep tapping the screen, all the dry screening particles clogged in and around the screen will be released, helping you to improve screening efficiency.

By using this anti blinding device, you can continuously screen your raw materials and boost your throughput.

Keeping your screens clean with the Mesh Deblinding Kit reduces the need to repeat the process of removing and cleaning your screens. This increases your productivity and allows you to work more effectively.

Through constant tapping, the elastomeric balls release and remove all clogging particles and lumps in and around the sieve.

Screens on ordinary screening machines wear out over time and become less efficient. As a result, you have to buy new machines, which increases your costs. You can extend the life of your screens by reducing wear and tear and using a Mesh Deblinding Kit.