Committed To Quality, Committed To You

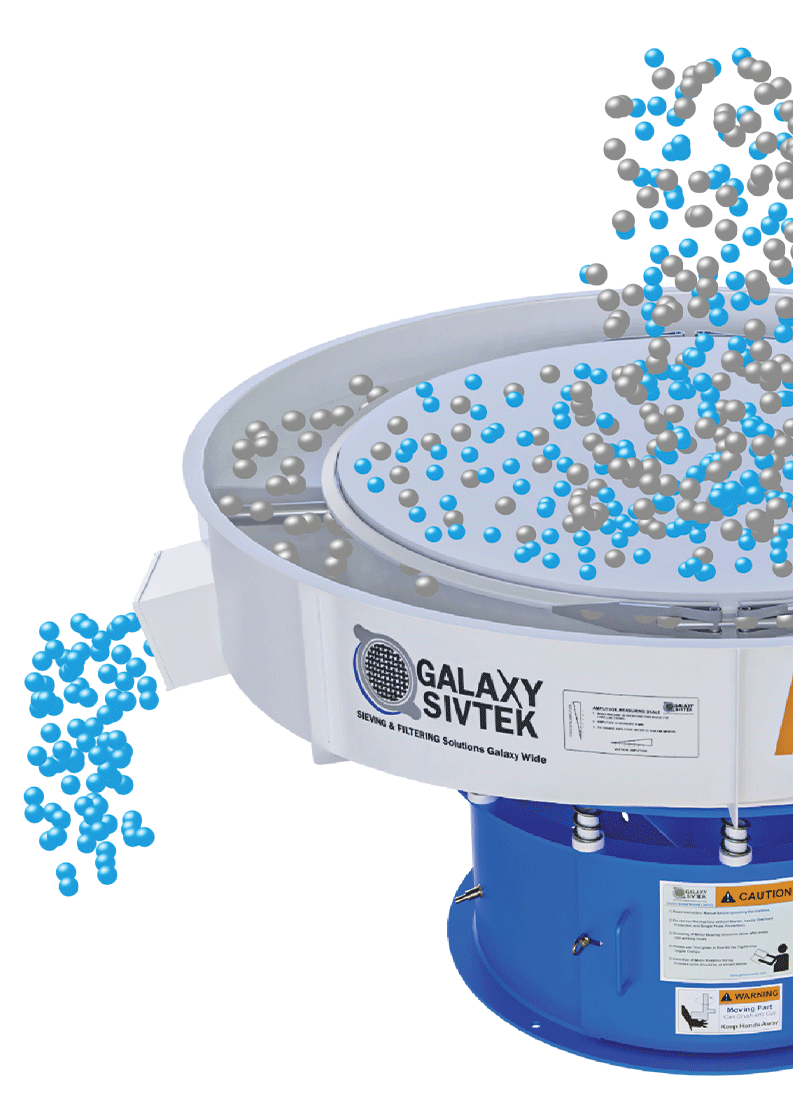

One of the best and most efficient industrial liquid filters is the SIVTEK 360° Discharge Separator. By rotating the screening material at a 360° angle, oversized particles are seamlessly discharged. As this inclined screening motion prevents oversized particles from accumulating on the screen periphery, it increases the discharge capacity of the screening process and lets you use the full screen area.

It has a high discharging capacity without clogging, so your mesh will last longer.

The design of the machine evenly discharges particles on the screen, which maximizes area usage.

The SIVTEK 360° Discharge Separator comes with three de-blinding add-ons to make cleaning easier.

This machine consumes less power than others, so it saves you money.

The filters provide the highest level of screening, and the cleaning disk ensures that the filters remain clean.

One of the most impressive features of our product is its ability to continuously process the substance, without any interruptions.