Case Study on customized Bag Dump Station

Overview

GSK is an internationally renowned healthcare company known for its constant innovation in the development of novel medicines to treat a wide range of critical diseases and infections. GSK is also well known for its nutritional and healthcare products, including Horlicks.

As part of the production of its nutritional products, the company imports skimmed milk powder from a reliable external source.

Requirement & Challenges

To ensure that skimmed milk powder is free of contamination, the company is required to check and screen the powder from external vendors before it is moved into the control room or used for production.

Due to the high likelihood of threads, or other foreign particles, being mixed with powder, check screening holds a prominent place.

It was quite difficult for them to manually dump the milk powder bags into screening machines for check screening due to the heavy weight of the bags they used to purchase from external vendors due to their heavy packaging, and if manual dumping is conducted, chances of contamination of the surrounding environment are increased.

Furthermore, when dusting milk powder manually, the amount of dust would be extremely high.

Concerns raised during/before/after the screening process.

Heavy bags make manual dumping difficult.

Contamination risks associated with the surrounding environment.

The production facility was subjected to intense dusting of milk powder.

Solution

During a technical meeting, Galaxy Sivtek experts provided the production department with a tailored solution for the check screening of milk powder. They concluded the meeting on a very positive note, as experts recommended the most tailored solution.

To overcome the problem of lifting heavy bags from storage, we constructed a system combining a conveyor belt with a Bag Dump Station in order to reduce lifting time.

To prevent contamination of the surrounding environment, we provided a completely enclosed bag dump station with a dust extraction system.

A dust extraction system assisted with overcoming the problem of material dusting in the air as it sucked up all the dust and threw it out, while air filters provided usable material back to the process.

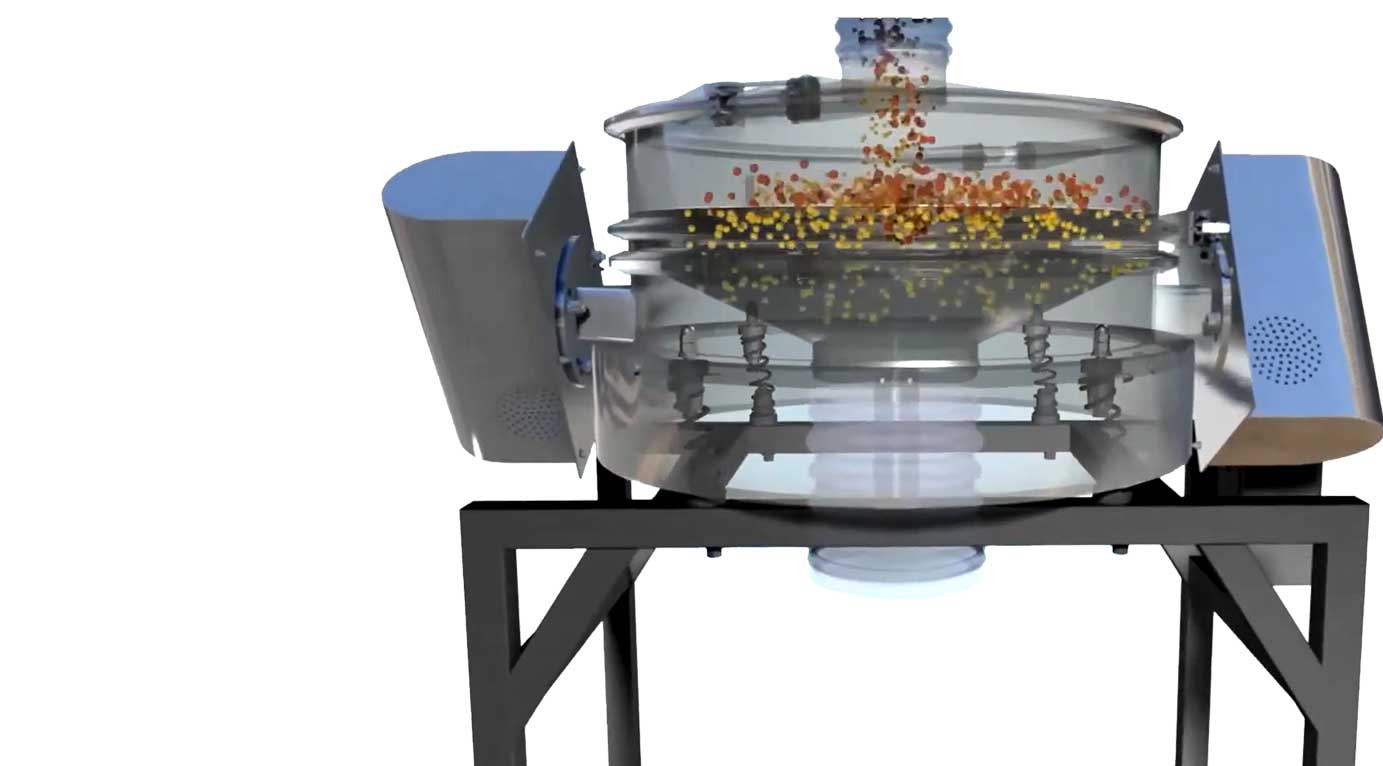

The team provided a complete solution with Inline Sivtek along with Conveyor Belts, Big Dump Stations with dust extractors, and a screw conveyor for check screening.

Results

According to the head of the production department, Galaxy Sivtek really understood the core of the problem and provided an exclusive solution. A member of my staff approached me and stated, “Sir, the upgraded system has made our work a lot easier – and that is exactly what we wanted”.

Moreover, he stated that “all the constraints we faced have been overcome by the system, whether it is the issue of lifting the heavy bags or the issue of dusting the materials. Everything is now in place.”.